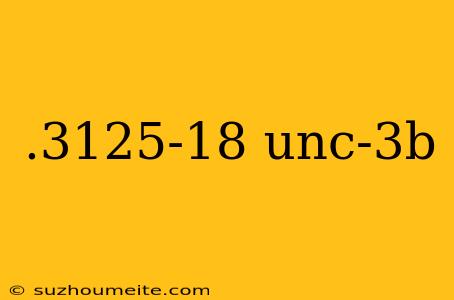

.3125-18 UNC-3B: Understanding the Specification

The .3125-18 UNC-3B is a specific type of screw thread commonly used in various industries, including aerospace, automotive, and construction. In this article, we will delve into the details of this specification and explore its significance.

What does .3125-18 UNC-3B mean?

Let's break down the .3125-18 UNC-3B specification:

- .3125: The nominal diameter of the screw thread in inches. In this case, the diameter is approximately 0.3125 inches or 8 mm.

- 18: The threads per inch (TPI). This means that there are 18 threads per linear inch of the screw.

- UNC: The thread series. UNC stands for Unified National Coarse, which is a standard thread series used in the United States.

- 3B: The thread class. The "3B" designation indicates that the thread has a tight tolerance, which ensures a secure fit and minimizes the risk of stripping or damage.

Characteristics and Applications

The .3125-18 UNC-3B screw thread is known for its:

- High strength-to-weight ratio: This thread is designed to provide exceptional strength while minimizing weight, making it ideal for applications where weight reduction is critical.

- Corrosion resistance: The thread is often made from corrosion-resistant materials, such as stainless steel or titanium, to withstand harsh environments.

- High torque resistance: The 3B thread class ensures that the screw can withstand high torque forces without stripping or damaging the threads.

The .3125-18 UNC-3B screw thread is commonly used in:

- Aerospace industry: For applications such as aircraft landing gear, engine mounts, and structural components.

- Automotive industry: For engine mounts, suspension components, and other high-stress applications.

- Construction industry: For structural components, such as anchor bolts and foundation bolts.

Conclusion

In conclusion, the .3125-18 UNC-3B screw thread is a specialized specification designed for high-stress applications where strength, corrosion resistance, and high torque resistance are crucial. Understanding the characteristics and applications of this thread is essential for designers, engineers, and manufacturers working in industries where reliability and performance are paramount.